Wholesale Retort Pouch Manufacturer

Bespoke Designs, Shapes, Size, Add-on Features | MOQ 10,00pcs+

- Retort pouches are a type of food packaging that has been used for decades. They are mainly used in the food industry to store and preserve food.

- They can be heated up in a microwave oven without any special equipment or preparation (which is not possible with other types of packaging).

- We have got the certifications from BRC, BSCI, FDA, CE, and ISO 9001

- Retort pouches are made of metalized plastic or aluminum foil.

- Food grade high barrier materials

- Cost-effective: Save packaging costs

- Provide protection from bacteria and other contaminants

- Stable product quality can help to avoid any claim or commercial loss

- Free retort pouch samples for quality reference

- Fastest quotation for custom printing pouches within 24 hours

- Provide an excellent barrier to oxygen and light, which is very important for the shelf life of the food.

- Retort pouches are ideal for packaging all kinds of food products, from meat to vegetables.

- 100% brand now raw materials, no recycled materials

Retort Pouch Could be A 3-Side-Seal Flat Pouch

Retort pouches are the most popular type of food packaging in the market. They are used for a wide range of products, from soups to sauces, and even baby food. Retort pouches are usually made from polyethylene and aluminum foil.

The retort pouch is sealed on three sides with a fourth side left open for filling. The pouch is then heated to sterilize the product inside before being sealed shut by heat or cold welding. This process ensures that the product will maintain its flavor, color, and nutritional content for an extended period of time.

Retort pouches are a type of food packaging that is sealed on three sides. They are made out of a heat-sealed plastic film, and they can be used to hold liquids or solids.

Retort pouches are often used for shelf stable products, such as soups, sauces, and frozen foods. They also can be used for dry goods such as powders and grains.

The main difference between lay flat retort pouches and 3 side seal retort pouches is the way in which they open. Lay flat retort pouches have one sealed end that opens like a book, while 3 side seal retorts have two ends that open like an envelope.

Retort Pouch Can be A Stand Up Pouch With Bottom Gusset

Retort pouches are used in the food packaging industry for high barrier and high temperature.

Retort pouches are a type of pouch that is designed to withstand high temperature and pressure. This makes them perfect for food packaging applications such as cooking sous vide, canning, or retorting.

The bottom gusset on the pouch stands up and provides easy access to the contents inside.

A retort pouch with bottom gusset is a type of food packaging that is usually used for high-temperature and high-barrier food products. It is a stand up pouch made of either aluminum or polyester, and it has a bottom gusset which can be sealed to make it airtight.

Retort pouches are made of polyethylene, Nylon, polypropylene, or a combination of the materials. It has a protective film on the inside and outside to protect the food from microbial contamination during retorting process.

Retort Pouch Could be In Spout Pouch Type

Retort pouches are a type of food packaging that is sealed and then heated to a high temperature for sterilization. The pouch is then cooled and opened so that the contents can be eaten. The spout retort pouch is a type of retort pouch with an opening on one side, which is used specifically for liquids.

A spout retort pouch is a type of food packaging that has a spout on the side or on the end of the package that allows for easy pouring or squeezing of liquid out of the package. These packages are usually used for soups, sauces, and other liquids that need to be poured out in a controlled manner.

Retort pouches are a food packaging option that can be used for liquid foods. They are made of a plastic-like material that is heat-sealed on the top and bottom. This allows them to be heated up in boiling water and then cooled down to room temperature without any damage to the package. They are often used for things like soups, sauces, or other liquids that need to be sealed in an airtight container.

The spout retort pouch is a type of retort pouch with a spout opening on one end. This allows the user to pour out the contents of the retort pouch without having to open it up completely. These pouches can come in different sizes and shapes depending on what they will be used for.

Clear Retort Pouch Is A Popular Food Packaging

Retort pouches are popular because they offer a total transparent look inside. You can see the food while it is still in the package, which makes it easier to see if there is anything wrong with the food.

Retort pouches are also popular because they offer a lot of protection for your food, even when it is exposed to high temperatures during shipping or cooking.

Retort pouches are popular because they are a total transparent to look inside. The food is also cooked inside the pouch, so it is ready to eat when it comes out. The retort pouch is made of either polyester or aluminum foil. Retort pouches can be used for many different types of food, but they are most commonly used for soups and sauces.

The transparent retort pouch is a popular food packaging because it allows you to see what you’re eating. It also cooks the food inside, so it’s ready to eat when you take it out. Retort pouches can be made from either polyester or aluminum foil and come in many different shapes and sizes.

Branded Printing Is Available for Retort Pouch

Retort pouches are a modern way of packaging food items. It is a flexible package made of polyethylene and is heat sealed on the top.

Retort pouch printing is done with a wide range of printing techniques, such as offset printing, flexo printing, screen printing and digital printing.

The retort pouch comes in many different shapes and sizes to suit the needs of the customer. It can be used for food products like soups, sauces, stocks, baby food and desserts.

With branded printing, retort pouches are not just a container for food anymore. They can be made into a marketing tool for brands.

Retort pouches are not just for packaging food anymore. They can be used to showcase the brand and values of the company with customized design.

Stand Up Retort Pouch Size Charts for Reference

All retort pouches are fully custom-made, including the features of sizes, shapes, colors, printing, etc. The follow size chart is only for reference, not standard.

Different products may go with different size, even they are of same weight.

| Volume (gram) | Volume (oz) | Width (mm) | Width (inch) | Length (mm) | Length (inch) | Gusset (mm) | Gusset (inch) |

|---|---|---|---|---|---|---|---|

| 28 | 1 | 80 | 3.15 | 130 | 5.11 | 40 | 1.60 |

| 70 | 2 | 110 | 4.35 | 160 | 6.30 | 60 | 2.35 |

| 100 | 3 | 120 | 4.75 | 200 | 7.90 | 60 | 2.35 |

| 150 | 4 | 130 | 5.10 | 210 | 8.25 | 60 | 2.35 |

| 250 | 8 | 160 | 6.30 | 230 | 9.05 | 70 | 2.75 |

| 500 | 16 | 190 | 7.50 | 265 | 10.20 | 90 | 3.55 |

| 1000 | 32 | 240 | 9.25 | 335 | 13.20 | 100 | 4.00 |

| 3000 | 106 | 300 | 11.8 | 500 | 17.90 | 70 | 2.75 |

| 4000 | 141 | 380 | 14.9 | 550 | 21.60 | 80 | 3.15 |

Plain retort pouch with Aluminum foil

-Retort pouches are made from aluminum foil or plastic. They are usually rectangular in shape and have a zip closure at the top.

-Retort pouches are a type of flexible packaging that is used to store and preserve food. They are typically made from aluminum foil, polyethylene or polypropylene.

Retort Pouch for Ready-to-eat Meal

-The pouch is made of a heavy-duty laminated material which protects the food from bacteria and keeps it fresh for long periods of time.

-Retort pouches are not only safe but also convenient as they can be cooked in boiling water for just a few minutes before consumption.

Stand up retort pouch for food packaging

-The type of food that can be packaged in this kind of pouch varies, but usually it is high-acid or low-acid foods such as soups, stews, and sauces.

-A stand up retort pouch has many advantages when compared to other types of packaging for high-acid or low-acid foods.

3-side seal lay-flat retort pouch with branded design

-Retort pouches are used in the food industry to store and preserve food. They are made of plastic or metal.

-Retort pouches are sealed on three sides with a three-sided seal, which is also known as a three-way seal. The seal can be made either by heat sealing or welding.

Customized printing retort pouch for food storage

-Retort pouches are also known as retortable pouches, retort packs, or food pouches. This type of packaging is popular because it can be used for a variety of products and applications.

-For instance, they can be used to store and preserve many types of food items such as soups, sauces, frozen vegetables, fruit drinks, and more.

Spout retort pouch with bottom gusset

-A spout retort pouch with bottom gusset is an excellent choice if you need to pour your product easily, have a wide variety of sizes, or are looking for something that can be microwaved.

OEM retort pouch with branded printing

-They are often used in food industries, such as restaurants, catering companies, and supermarkets.

-Retort pouches are made of a strong, heat-resistant plastic that is used in the production of various food items.

Vacuum retort pouch with metallized foil

-Vacuum retort pouches are made from polymers that have been exposed to heat and steam in order to make the material pliable.

-The metalized foil on the inside of the pouch blocks oxygen from entering while allowing heat and moisture to escape.

The Complete Purchase FAQ Guide to Retort Pouch

Part 0: Retort Pouch Purchase FAQ

Q: What is the retort pouch?

The retort pouch is a lightweight, durable, and flexible packaging that has been used to store food in the form of a pouch. It is usually made out of plastic or metal foil and is an effective way to preserve food for long periods of time.

A retort pouch is a sealed container that contains a pre-cooked, vacuum-sealed food product. This packaging has been primarily used for ready-to-eat meals in the military and by relief organizations. They are very popular with airlines because they can be heated up without any fuss or mess.

Retort bags provide a way to keep food safe from contamination for a long period of time. The bags can be used in many different ways, such as storing raw meat or canned goods. They are perfect for people who need to keep their food fresh while they travel or camp outdoors.

Q: How to use retort pouch?

The retort pouch is mainly used for cooking food at high temperatures. It is a sealed plastic bag that can be heated up in boiling water or in an oven.

The aluminum foil has many functions, it can be used as a cooking pan liner to keep food from sticking to the pan. It can also be used as a heat shield to protect the surface of something that is being cooked on the stove.

Q: How to seal retort pouch?

A retort pouch is a type of food packaging that is sealed with a heat-sealing machine. The machine will seal the retort pouch with a hot air and pressure process. This process ensures that the pouches are safe for consumption and that they don’t leak or spill their contents.

Q: What’s the benefits of retort pouches?

Retorts pouches are a great way to cook food quickly and efficiently. They are lightweight, easy to store, and come in a variety of sizes.

Retorts pouches are made of two layers of plastic that sandwich the food inside. The top layer is sealed with an airtight seal and the bottom layer has an opening that is sealed with heat-sealed edges. The food inside can be cooked using steam or boiling water, depending on how it is prepared before being placed into the retort pouch.

There are many ways to use retorts pouches in your everyday cooking habit. You can prepare meals ahead of time for your family or even freeze them for later use!

Q: Is the retort pouch eco-friendly?

Retort pouches are a type of food packaging that is environmentally friendly and sustainable.

Retort pouches are made from materials that are eco-friendly, such as polyester. They are also recyclable and can be reused for up to 10 years. For these reasons, retort pouches are the perfect packaging solution for food manufacturers.

Q: Why is the retort pouch best packaging for ready-to-eat meal?

The retort pouches are an excellent choice for ready-to-eat meals because they do not require any additional preparation before consumption and can be stored at room temperature without heating or cooling them first.

Retort pouches are an innovative way of packaging food. They are made by sealing food in a pouch and then heating it up to sterilize the food. This process kills all the bacteria that could be present in the food, making it safe for consumption. The retort pouch is also an ideal way to store ready-to-eat meals because it provides a stable environment for the food inside, which means that you don’t need to refrigerate it.

Q: Can you microwave a retort pouch?

Retort pouches are a type of food packaging that is commonly used to preserve and prepare food. It can be cooked, frozen, microwaved, and heated in a pressure cooker.

The retort pouch is made up of two sheets of metal with a plastic layer between them. The process starts off by cooking the food inside the metal sheets and then sealing it with the plastic layer to create an air-tight seal.

The microwave can be used to heat up retort pouches because it uses electromagnetic waves which penetrate the plastic and heat up the food inside.

Q: What Are Retort Pouch Meats and Are They Safe?

Retort pouch meat is a food product that has been sealed in a watertight plastic pouch. It can be cooked by boiling or steaming and is often used for camping, hiking, and other outdoor activities.

Retort pouches are made from a special type of plastic that can withstand high temperatures without breaking down. The retort pouches don’t need refrigeration until they are opened.

The retort pouch meats are safe to eat because they have been processed to kill any bacteria that may be present in the meat before it is sealed in the retort pouch.

Q: Will you provide Free samples of retort pouches for testing and quality checking?

Yes, Ouma Flex Pack will offer Free samples of different retort pouches to the customers, for quality reference, total free of charge.

Q: Do Ouma Retort Pouches pass FDA testing?

All Ouma flexible packaging bags and retort pouches, including stand up pouches, retort spout pouches meet the testing standards of BRC, FDA, and CE.

Q: What is retort pouch production lead time?

Normally it will take 2 weeks to 3 weeks to make the cargo ready. But it will also depend on the sales season, order qty, production requests, printing, etc.

Q: What is the MOQ for the Retort pouch?

For retort pouch, the MOQ is 10,000 pcs per SKU normally (same size, same printing).

But we will offer special treatment for trial orders and new-started projects by lowest MOQ of 1000+.

Q: What are the trade terms? What are the terms of payment? What are the methods of payment accepted?

Trade terms: We normally deal with the terms of CIF / FOB / EXW. The regular shipping way is: Ocean shipment, Air shipment, Handcarry dispatches.

Terms of Payment: The terms of payment is 30% – 50% down payment, balance prior to cargo delivery from our factory.

Methods for payment: We will agree to accept the payment sent via Wire transfer / Paypal / Western Union / Letter of Credict.

Part 1: Definition of Retort Pouch

Retort pouches are a type of packaging that is used for food products. The pouch is sealed at the top and bottom, and the food inside it has a long shelf life.

Retort pouches are used for high-temperature sterilization of food products such as meats, vegetables, fruits, and soups. They are also used for storage of ready-to-eat meals. The seal on these bags ensures that there is no contact with air or moisture which can lead to spoilage of the product inside it.

Retort pouches are a type of packaging that is used for cooking and storing food. They come in different shapes and sizes and can be used for both hot and cold foods.

Retort pouches are an alternative to cans, jars, or glass containers. They have a lot of benefits over these types of packaging, such as being more environmentally friendly, safer to use, more convenient to store, easier to open and close, etc.

Part 2: Applications of Stand Up Pouch

A retort pouch is an airtight, flexible package made of metalized polyester. It is used to store food and other products that need to be preserved.

A retort pouch is an airtight, flexible package made of metalized polyester. It is used to store food and other products that need to be preserved. They are typically used for field rations, space food, fish products, camping food, instant noodles or pre-cooked meat.

Retort pouches are a lightweight, pre-cooked, and shelf stable package that is usually used for field rations. It has a hermetic seal and can be heated in boiling water or microwaved.

Retort pouches are an excellent alternative to cans because they do not have the same weight and volume restrictions. They are also more environmentally friendly because they don’t require a can opener or can opener skills.

Retort pouches are perfect for camping food because they save you from having to cook your food on the spot. They can also be used as instant noodles in case you don’t have access to any other cooking supplies.

Part 3: Retort Pouch Add-on Accessories

Different industries go with different packaging, with different features and functions. It’s important and necessary to offer custom-designed retort pouches to different clients.

Various accessories will be applied to Ouma retort pouches, which will bring many extra functions. It will make it easier for customers and retailers when opening, packing, resealing.

It’s totally customized to use what kinds of add-ons for your bespoke retort pouch. Or just reach us with the full detail request, we will offer you the best solutions, based on your market demands.

3.1: Resealable Ziplocks

Resealable retort pouches are flexible packaging with a pressure seal closure. These retort pouches are now widely used everywhere.

Such as processing and storing food, retailing items of any size or serving the healthcare needs of patients in hospitals, medical and dental offices, pharmacies, home health care or pharmaceutical production. You almost find these bags.

3.2: Hanging Punch Holes

Hanging on the shelf is another way of displaying your products on the supermarket, besides standing up on the shelf.

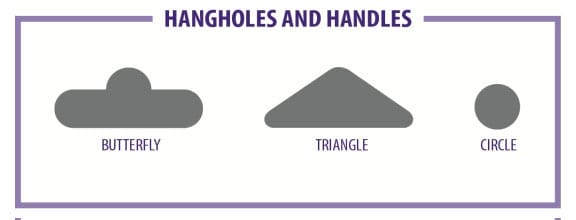

To meet different demands, we offer 3 different hanging holes: Butterfly (also called Euro) hole / Triangle hole / Round hole. These holes will be done by punching tooling. The sizes of holes are customized as you need.

3.3: Retort Pouch Rounded Corners

The bigger pouches, the thicker materials. The thick materials make the retort pouch strong and stiff enough, but it goes with sharp corners as well.

To avoid any unexpected injuries, we offer the options of rounded corner coffee bags. This will make it safe for all consumers, no matter adults, aged or children.

3.4: Tear Notches

The start for the consumer to use or consume your product is Opening the pouches, easily, without any tools. This is one of the most important factors for a succeed brand.

So we will add tear notches to most of flexible packaging bags, to increase customer convenience.

3.5: Stand Up Retort Pouch Bottom Types

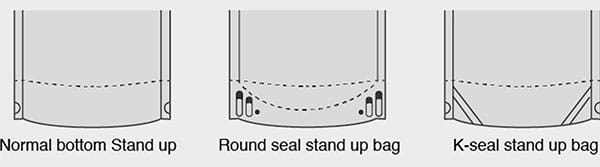

There are 3 different bottom gusset type for stand up retort pouches: Normal bottom / Round Seal Bottom / K-Seal Bottom. The first 2 types are the most common pouch bottom types.

Part 4: Retort Pouch Types

Retort pouches are a type of food packaging that is used to preserve food. They are made of heat-sealed, flexible, transparent plastic film, and they are originally designed and used in the preparation of meals for astronauts.

Retort pouches can be used to preserve many types of foods such as soups, vegetables, meat and fish dishes. They can also be used to package ready-to-eat meals like pasta or rice dishes.

4.1: Metallic Foil / Aluminum Foil Stand up Retort Pouch

A retort pouch is a type of flexible packaging that is used to store food products. Retort pouches are made of aluminum foil and can be sealed with heat or cold. Aluminum foil stand up retort pouch is a high barrier food packaging that has a bottom gusset and can be self-standing.

The main purpose of this type of packaging is to provide a hermetic seal for the product so that it can be heated or frozen without any leakage. The aluminum foil prevents the air from getting into the package which prevents oxidation and preserves the quality of the product inside.

The aluminum foil stand up retort pouch is made from a metalized aluminum material that resists oxygen, moisture, and light. The metalized surface also helps with the heat seal process and ensures that the package maintains its shape.

4.2: Transparent Retort Pouch

A transparent retort pouch is a type of food packaging that has high temperature resistance. They are usually made from polyester, and the inside can be seen through the clear view. Retort pouches have a variety of uses and can be used for liquid or solid foods.

This kind of retort pouch is mainly used for sterilized food to keep it fresh for a long time. The heat treatment in the process will kill bacteria and make the food safe to eat.

The transparent retort pouch is often used by food companies because they can offer their consumers a clear view of what they are buying. This packaging also allows them to heat up the food in a retort, which kills all bacteria and makes it safe to eat without cooking or refrigerating it.

4.3: Metallic Foil Lay-flat Retort Pouch

The flat retort pouch with 3 side seal is a type of food packaging that is used to store and preserve food items. The main difference between it and other types of food packaging is the shape of the package.

The flat retort pouch with 3 side seal has a rectangular shape that can be sealed on three sides, which means that it can be opened from one end for filling or emptying. It is also easier to stack than other types of packaging, which makes it more efficient for storage and shipping.

4.4: Customized Retort Pouch with Branded Printing

Retort pouch is a type of heat-resistant packaging that is widely used in the food industry. It can be customized and printed with branding.

Retort pouches are made of polyester, aluminum or other types of materials with a high melting point. The packaging is sealed by heat sealing and vacuum sealing. Retort pouches are generally used for packaging hot and cold food products, such as soups, sauces, vegetables, fruits, meats and seafoods.

The advantages of retort pouches include low cost per unit weight compared to glass or metal cans, good barrier properties against oxygen and vapor transmission (for canned foods), protection against light exposure (for products that need to be protected from light), protection against corrosion (for products containing salt or vinegar) and good barrier properties.

4.5: Shaped Retort Pouch

Retort pouches are a popular choice for food packaging because they are lightweight, flexible, and easy to seal.

Retort pouches are made of polymers which is a type of plastic that is heat-resistant. The polymer material can be formed into any shape and size. Retort pouches with fancy shapes have been on the rise in recent years as more people want to customize their food packaging.

A retort pouch with fancy shapes will give your product the edge over other products on the market. It will also help you to stand out from competing brands.

4.6: Spout Retort Pouch

Retort pouches are a versatile packaging solution that can be used in various industries. They have been designed to replace the traditional cans or glass containers. A retort pouch with spout is a type of retort pouch that has a spout on the side, which makes it easy to pour out the content without opening the package.

A retort pouch with spout is an innovative and convenient way to package food items. It can be used in various industries such as food service, healthcare, and retail. The product is made from high-quality materials and has been designed to replace cans or glass containers for its versatility and convenience features.

Retort pouches are a type of food packaging that is sealed with a spout. They are made from a flexible, heat-sealed plastic and they can be reused after they’ve been opened.

Some retort pouch packaging come with a spout, which makes them easier to pour out of and to store. This is especially helpful for people who want to store their ingredients in the fridge before cooking them or who want to make sure that they don’t spill the contents all over their countertops when pouring the ingredients into a pot or pan.

Part 5: Retort Pouch Material Guide

To keep the content flavor and freshness, retort pouch with the capability to be the significant need. Precisely, when these packages reach to the market consumer, food flavor must be fragrant and taste the same as it is originally.

Retort pouch from Ouma are a great promotional packaging that could be used as it will encourage purchases. Stand up pouch can be printed with custom-designed artwork, up to eight colours.

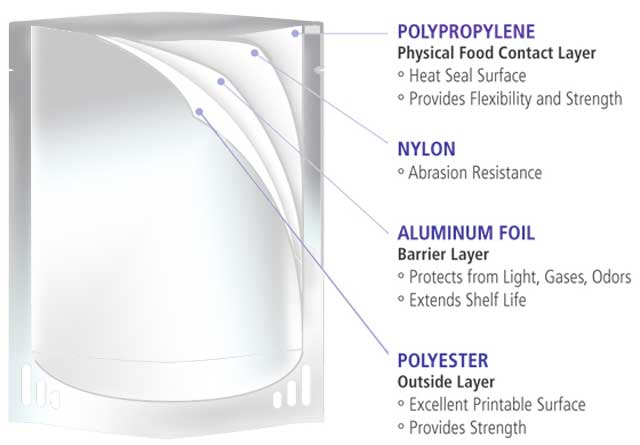

The most popular materials used for retort pouch include: PET / PE / CPP / VM PET / NY / Aluminum Foil.

LDPE(Low-density polyethylene): is widely used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic parts for computer components, and various molded laboratory equipment. Its most common use is in plastic bags.

HDPE (High-density polyethylene): is known for its high strength-to-density ratio. This plastic is usually milky white or semi-translucent, has superior puncture, low permeability and temperature resistance, and is more rigid and stronger than LDPE / LLDPE but also tears easier and has a propensity to crinkle.

PVDC: Polyvinylidine chloride, the excellent oxygen and moisture barrier properties of PVDC make it a ideal material for packaging converters. But the high cost of PVDC tends to mean that it is mainly used in the form of copolymers.

PET: Polyethylene terephthalate, is a very strong clear glossy film, and possesses a great number of advantages, such as good moisture and gas barrier properties, tensile strength, etc.

BOPP (Biaxially-oriented polypropylene): BOPP films are easy to produce with low costs. They have good chemical compatibility and offer superior moisture vapor barrier properties.

(Kraft) paper: has high tensile strength and elasticity, good tear resistance and is designed for packaging products with high demand for strength and durability. It is used for products like single multiwall paper bags and sacks (for cement, food, chemicals, consumer goods, flour bags etc.), sale bags for bakery products, wrapping.

Aluminum foil and metalized substrates: Aluminum foil has the best dead fold properties. It provides an excellent 100% barrier to all gases, moisture and light. It is a good reflector of radiant heat, usually supported with plastic and/or paper (in multy-layer structure) because it cracks when folded. Alone does not provide an acceptable aroma or odder barrier.

Metalized PET: are polymer films coated with a thin layer of metal, usually aluminium. They offer the glossy metallic appearance of an aluminium foil at a reduced weight and cost.

EVOH (Ethylene Vinyl Alcohol): is produced by a controlled hydrolysis of ethylene vinyl acetate copolymer. It’s most important characteristic is the outstanding Oxygen and odor barrier properties. Packaging structures with EVOH provide high retention of flavors, and prevent quality loss associated with reaction of oxygen with the product.

CPP (Cast Polypropylene): offer excellent heat seal strength, good thermal stability, good puncture resistance, good clarity and fair barrier properties. The film type also has good yield economics owing to its low density. Some of the typical application areas for the film includes hot filling and retort applications, high speed application on FFS machines and bakery products.

PLA (Polylactic acid): Polylactic acid is thermoplastic aliphatic polyester synthesized from renewable biomass, typically from fermented plant starch such as from corn , cassava , sugarcane or sugar beet pulp. In 2010, PLA had the second highest consumption volume of any bioplastic of the world. PLA is compostable, but non-biodegradable according to American and European standards because it does not biodegrade outside of artificial composting conditions.

PBS (Polybutylene succinate) : Polybutylene succinate is a thermoplastic polymer resin that has properties comparable to propylene. It is used in packaging films for food and cosmetics. In the agricultural field, PBS is used as a biodegradable mulching film PBS can be degraded by Amycolatopsis sp. HT-6 and Penicillium sp. strain 14-3. In addition, Microbispora rosea, Excellospora japonica and E. viridilutea have been shown to consume samples of emulsified PBS.

Ouma stand up pouches can be manufactured by different multi-ply lamination, according to packaging purposes:

- PET / PE

- MATT BOPP / PET / PE

- PET / ALU / PE

- MATT BOPP / METALLIC PET / PE

- KRAFT / PET / PE

- KRAFT / ALU / PET / PE

- BOPP / CPP

- PET / NY / PE

- Kraft // PLA

- PLA // NKME // PLA

- NK // PBS

- Others by requests

The main materials we use for Ouma coffee bags are certificated by FDA. You could get all our materials certificates by just simply sending us an email.

Part 6: Ouma Tips for Retort Pouch

Qualified retort pouch will bring you both long shelf life span and powerful marketing. It also create a wonderful emotional connection between your brand and the consumers. But it takes time to have enough experiences on the production of retort pouch.

Many clients do not produce the retort pouches themselves. But it’s important to have the knowledge about production technology, which will help you understand what’s the qualified retort pouch, and who is the trusted and qualified manufacture

and partner of your retort pouch.

Tips #1:

The High temperature steamed pouch: stand for max 125 ℃ and 30 min.

Tips #2:

There are transparent retort pouch and opaque retort pouch.

The transparent pouch is normally made of PET or PA +CPP. The opaque retort pouch has an extra middle layer of aluminum foil or metallic PET foil.

Tips #3:

Due to the slow heat transfer when the transparent bag sterilization, so the transparent retort bag is suitable for small packages with contents below 300 grams. Contents of more than 500 grams need to use aluminum foil opaque retort pouches.

OUMA Retort Pouch For Ready-To-Eat Meat

Ouma flex pack has been in the industry for more than 20 years. We are one of the most professional manufacturers in China. Ouma retort pouches cover a wide range of pouch types: stand up doypacks, flat pouch, spout pouches, vacuum pouches, etc.

Our retort pouches are fully customized, ranging from 2 oz to 25 lb. Our innovative packaging help you succeed in your local markets. We have set up 3 fully-owned plants, taking control of most processes to produce. We have built up a triple-100% inspection working systems, assuring that only qualified bags and pouches will be delivered.

With us, your business is safe! Your money is safe!

We offer a lowest MOQ request compared with other China vendors. It helps to lower the risks and costs when the client wants to start a new project and make a trial shoot.

We are always there when you need any helps from us, 7*24. You can reach us easily, with email, cell phone, telephone call, whatsApp, Wechat, etc.