Flat Bottom Box Pouches Manufacturer

It’s also called Box bottom Pouches, Block bottom Bags.

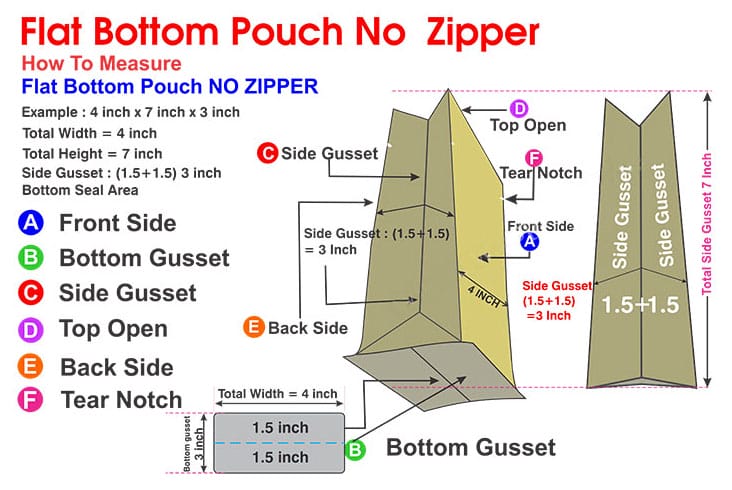

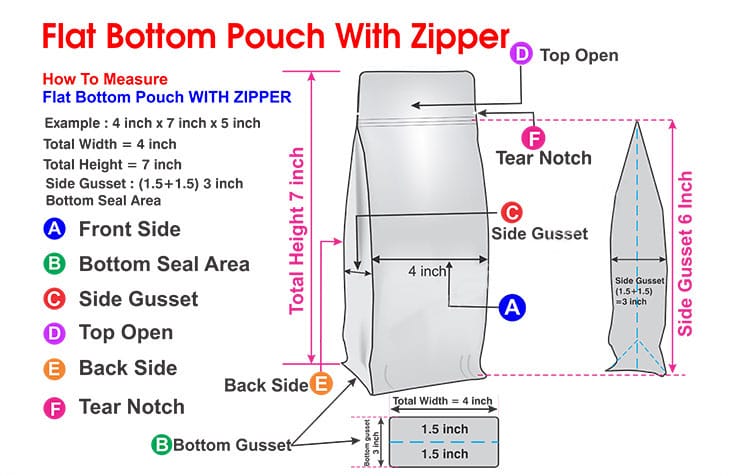

Flat Bottom Pouches have completely flat bottom and so they are known as “Flat Bottom Pouches”. These are also known as “Box Pouches”. The flat bottom allows all kinds of products for sturdy storage. It holds more weight in compare to Bottom Gusset Pouches or Side Gusseted Pouches.

These pouches have gussets on left and right side, they have gusset on bottom too. The flat bottom of this pouch has been designed smartly for an attractive appearance at the sale counters with its wide range of printable surfaces. Moreover it has great shelf stability which aids for sturdy storage too.

Box Pouches enable your products to stand out on retail shelves. Ideal for granulates, powders, and other dry goods, Box Pouches convey high quality and convenience to consumers.

Flat Bottom | Box Bottom Stand up Pouches

Made of plastic laminations or plastic & kraft laminations

Plastic Lamination Flat Bottom Pouches

Also called box bottom pouches, block bottom bags

Regularly made of plastic films of:

PET / CPP / MOPP / Metallic PET / PE / Nylon

The choice of films depends on what functions is required

For more info about material structurer, please click the link

Plastic & Kraft Lamination Bottom Gusset Pouches

Regularly made of :

Kraft papers & Plastic films

This pouch type offer another performance of packaging

Click here to learn more about kraft bags & pouches

Metallic Box Pouches Are Another Important Packaging Types

Regular metallic colors:

Golden / Silver

Custom printing is available for metallic pouches

Three Closure Types of Flat Bottom Box Pouches

Resealable Ziplock Closure

One of most important add-on to flat bottom standing pouches

Resealable / Reclosable: Eco-friendly

An important tool to keep content fresh

Tin Tie Closure

Tin Tie is another popular closure for flexible packaging bags

Easy opening and closing in seconds

Open End Heat Sealing Closure

Available for branded label stickers

Another option is to seal by a heating closure

Eco-friendly closure

Different Pouch Structures of Box Pouches

Features and Options (Add-Ons) of Stand Up Pouches

Transparent / Clear Shaped Window

Opening a window to have inside look

Custom window shape & size

Custom Printing Pattern

Fully custom printing design of customers

Printing pattern from 1 color to 8 colors

Best brands promotion

Discharging Valves

Single-way degassing valve

Get rid of air inside out

Best for coffee beans, food packaging

Die-Cut Hanging Hole / Handle

A die-cut hanging hole or round hanging hole

Die-cut handle also available

Offering a different way of displaying in supermarkets

Regular Size Chart for Flat Bottom Box Pouches

| Volume (MT) | Volume (EN) | Width (mm) | Width (inch) | Length (mm) | Length (inch) | Gusset (mm) | Gusset (inch) |

|---|---|---|---|---|---|---|---|

| 100 gs | 4 oz | 90 | 3 5/9 | 185 | 7 7/25 | 55 | 2 1/6 |

| 250 gs | 8 oz | 95 | 3 5/7 | 238 | 9 | 70 | 2 5/7 |

| 340 gs | 12 oz | 127 | 5 | 200 | 8 | 80 | 3 1/8 |

| 500 gs | 16 oz | 112 | 4 3/8 | 280 | 10 7/8 | 80 | 3 1/8 |

| 1000 gs | 2.2 lbs | 146 | 5 3/4 | 343 | 13 1/2 | 102 | 4 |

| 1180 gs | 2.6 lbs | 150 | 5 3/4 | 330 | 13 | 118 | 4 5/8 |

Remarks: Pouch sizes are fully customized. It’s not fixed, you can decide the pouch dimensions according to your products!

Frequently Asked Questions

Q1: Is Ouma a trader or a real manufacturer flexible packaging products?

A1: Ouma has been a flexible packaging bags & pouches converter for more than 20 years. We are a trusted flexible packaging expert.

Q2: What’s the MOQ of flexible bags & pouches / flexible rolls to purchase?

A2: For bags & pouches, the MOQ for each size in each design is 10,000pcs; for flexible film rolls, the MOQ for each size in each design is 100kgs.

Q3: What’s the payment methods available & terms of payment?

A3: The available payment methods is: T/T, Paypal, Western Union, L/C; Terms of payment: 30% deposit upon order, balance before cargo delivery.

Q4: Do you offer samples for quality checking?

A4: Ouma offers existing samples free of charge for quality checking. If you would like to have samples 100% same as your order, there will be sampling charges.

Q5: What is mass order production lead time?

A5: For orders of LCL, the regular lead time is within 14 days; for FCL orders, the regular lead time is within 21 days.

Q6: What is trade terms for mass orders?

A6: Ouma regularly deal with trade terms of EX WORKS, FOB, C&F, CIF.

Flexible Pouches & Bags Applications

Ouma Flexible Packaging has the technology and expertise to manufacture customized pouches for a wide array of products.

- Condiments

- Dressings

- Marinades

- Spreads

- Jams

- Peanut butter

- Honey

- Sauces

- Syrups

- Butter & shortening

- Cooking oils

- Vinegar

- Baby food

- Fruit Purees

- Yogurt

- Water

- Juices

- Sports drinks

- Energy drinks

- Dairy drinks

- Alcoholic beverages

- Protein shakes

- Coffee drinks

- Sugars & sweeteners

- Spices & Seasonings

- Nuts, seeds, & Grains

- Trail mix

- Confectionary & candy

- Pet food

- Powdered drink mixes

- Lotions

- Conditioners

- Shampoos

- Gels

- Creams

- Ointments

- Oil

- Lubricants

- Laundry detergent

- Cleaners

- Stain removers

- Insect repellents

- Bath crystals

- Dish soap

- Hand soap

Triple-100% Quality Control Process

Our first priority is to offer qualified products 100% upto requirement. To achieve the goal, we set up a Triple-100%-Quality-Control-Process. With it, we have been offering fully qualified pouches and bags to the global market.