Bottom Gusset Stand-up Pouches Supplier

Bottom gusset pouches are the most popular and commonly used stand-up pouch (SUP) in the industry and is ideal for light weight products.

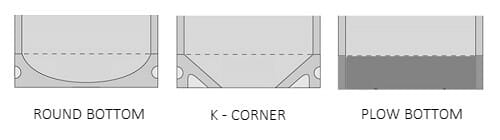

It is a sealed plastic pouch and has a round bottom; it has been designed in a way that it can stand up-right. The edge of the gusset is welded to the sides of the walls for better strength and support.

K-Seal Bottom and Plaw Bottom are two more types of bottom gusset pouches which are modified from the round bottom pouches for extra weight capacity.

Bottom Gusset Pouches are normally used for storing food and non-food items. These pouches can be aseptically filled or with the help of packaging lines.

Stand up pouches are made of plastic laminations or plastic & kraft laminations

Plastic Lamination Bottom Gusset Pouches

Regularly made of plastic films of:

PET / CPP / MOPP / Metallic PET / PE / Nylon

The choice of films depends on what functions is required

For more info about material structurer, please click the link

Plastic & Kraft Lamination Bottom Gusset Pouches

Regularly made of :

Kraft papers & Plastic films

This pouch type offer another performance of packaging

Click here to learn more about kraft bags & pouches

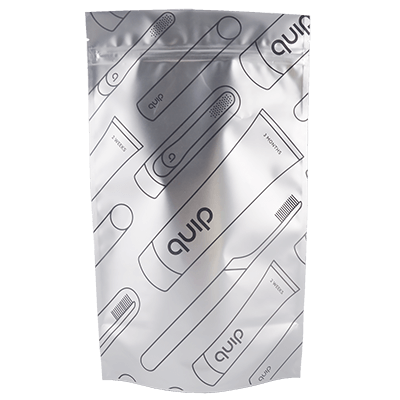

Metallic Stand Up Pouches Are Another Important Packaging Types

Regular metallic colors:

Golden / Silver

Custom printing is available for metallic pouches

Solid Back / Clear Front Standing Pouches

A Special Standing Pouch Type

The backside is in solid opaque color

The frontside is in 100% transparent material

Features and Options (Add-Ons) of Stand Up Pouches

Resealable Ziplock Closure

One of most important add-on to bottom gusset standing pouches

Resealable / Reclosable: Eco-friendly

An important tool to keep content fresh

Transparent / Clear Shaped Window

Opening a window to have inside look

Custom window shape & size

Custom Printing Pattern

Fully custom printing design of customers

Printing pattern from 1 color to 8 colors

Best brands promotion

Discharging Valves

Single-way degassing valve

Get rid of air inside out

Best for coffee beans, food packaging

Die-Cut Hanging Hole / Handle

A die-cut hanging hole or round hanging hole

Die-cut handle also available

Offering a different way of displaying in supermarkets

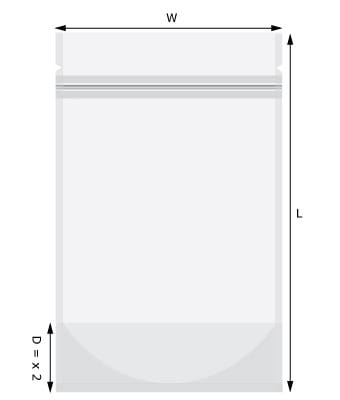

How We Measure Pouch Dimensions

W= Pouch width (eg: 5 in)

H= Pouch height (eg: 8 in)

D= Pouch gusset depth x 2 (eg: 1.5 in)

In this case, the correct dimension is: “W 5in / H 8in / D 3in”

Regular Size Chart for Stand Up Pouches

You can create your own custom pouch sizes!

| Volume (gram) | Volume (oz) | Width (mm) | Width (inch) | Length (mm) | Length (inch) | Gusset (mm) | Gusset (inch) |

|---|---|---|---|---|---|---|---|

| 28 | 1 | 80 | 3.15 | 130 | 5.11 | 40 | 1.60 |

| 70 | 2 | 110 | 4.35 | 160 | 6.30 | 60 | 2.35 |

| 100 | 3 | 120 | 4.75 | 200 | 7.90 | 60 | 2.35 |

| 150 | 4 | 130 | 5.10 | 210 | 8.25 | 60 | 2.35 |

| 250 | 8 | 160 | 6.30 | 230 | 9.05 | 70 | 2.75 |

| 500 | 16 | 190 | 7.50 | 265 | 10.20 | 90 | 3.55 |

| 1000 | 32 | 240 | 9.25 | 335 | 13.20 | 100 | 4.00 |

| 3000 | 106 | 300 | 11.8 | 500 | 17.90 | 70 | 2.75 |

| 4000 | 141 | 380 | 14.9 | 550 | 21.60 | 80 | 3.15 |

Remarks: Pouch sizes are fully customized. It’s not fixed, you can decide the pouch dimensions according to your products!

Frequently Asked Questions

Q1: Is Ouma a trader or a real manufacturer flexible packaging products?

A1: Ouma has been a flexible packaging bags & pouches converter for more than 20 years. We are a trusted flexible packaging expert.

Q2: What’s the MOQ of flexible bags & pouches / flexible rolls to purchase?

A2: For bags & pouches, the MOQ for each size in each design is 10,000pcs; for flexible film rolls, the MOQ for each size in each design is 100kgs.

Q3: What’s the payment methods available & terms of payment?

A3: The available payment methods is: T/T, Paypal, Western Union, L/C; Terms of payment: 30% deposit upon order, balance before cargo delivery.

Q4: Do you offer samples for quality checking?

A4: Ouma offers existing samples free of charge for quality checking. If you would like to have samples 100% same as your order, there will be sampling charges.

Q5: What is mass order production lead time?

A5: For orders of LCL, the regular lead time is within 14 days; for FCL orders, the regular lead time is within 21 days.

Q6: What is trade terms for mass orders?

A6: Ouma regularly deal with trade terms of EX WORKS, FOB, C&F, CIF.

Flexible Pouches & Bags Applications

Ouma Flexible Packaging has the technology and expertise to manufacture customized pouches for a wide array of products.

- Condiments

- Dressings

- Marinades

- Spreads

- Jams

- Peanut butter

- Honey

- Sauces

- Syrups

- Butter & shortening

- Cooking oils

- Vinegar

- Baby food

- Fruit Purees

- Yogurt

- Water

- Juices

- Sports drinks

- Energy drinks

- Dairy drinks

- Alcoholic beverages

- Protein shakes

- Coffee drinks

- Sugars & sweeteners

- Spices & Seasonings

- Nuts, seeds, & Grains

- Trail mix

- Confectionary & candy

- Pet food

- Powdered drink mixes

- Lotions

- Conditioners

- Shampoos

- Gels

- Creams

- Ointments

- Oil

- Lubricants

- Laundry detergent

- Cleaners

- Stain removers

- Insect repellents

- Bath crystals

- Dish soap

- Hand soap