What Are The Benefits Of Compostable Pouches?

The compostable pouch is a heat-sensitive, breakable container to store food. The pouch is soft and pliable and can be flattened like an empty bag of chips. It is made from plant-based materials that break down in the presence of oxygen, sunlight, and water.

The main benefits of compostable pouches include:

- They can compost in as little as six weeks (compared to two years for traditional plastics)

- They are odorless and do not need to be sealed to prevent

- Compostable pouches are a sustainable alternative to plastic bags because they are made from natural and renewable materials

- They are not made with any harmful chemicals, toxins, or petroleum products

- They can be recycled along with food scraps and other compostable items

- The process of biodegradation makes these pouches non-toxic and suitable for landfills

- The material is also designed to be more flexible and stretchable, which makes it easier to seal

- Compostable, biodegradable, and degradable pouches are an environmentally friendly alternative to plastic bags

- Compostable bags are free from the toxic chemicals that are found in plastic bags, such as BPA and phthalates

- Compostable bags create less waste than plastic bags

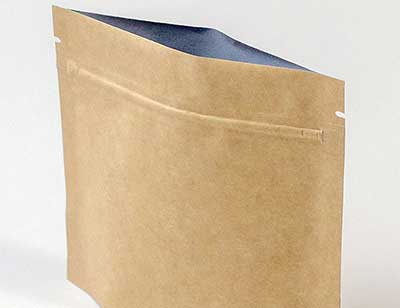

Stand Up Compostable Pouch Is The Most Popular Food Packaging

The stand up compostable pouch is the most popular food packaging for a number of reasons. The stand up pouch is lightweight and it can be made from a variety of materials.

The stand up compostable pouch can be used to package all sorts of different food products, such as rice, noodles, and oatmeal. This type of packaging is also great for people who want to eat healthier because it doesn’t contain any plastic or chemicals.

Stand up compostable pouches are the most popular food packaging in the past few years. They are used to package a wide range of food products, such as chips, nuts, cookies and crackers.

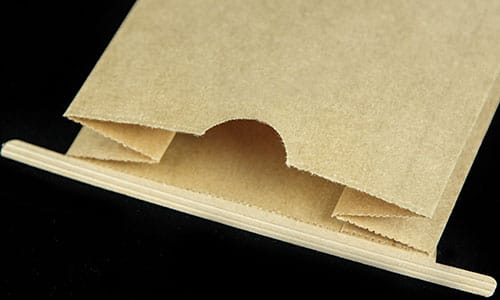

The bottom gusset is a design element that can be found on stand up pouches. It is used to give a little more shape to the package so it can stand up on its own.

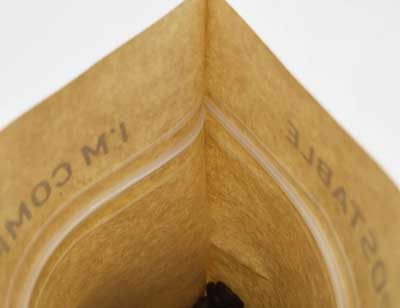

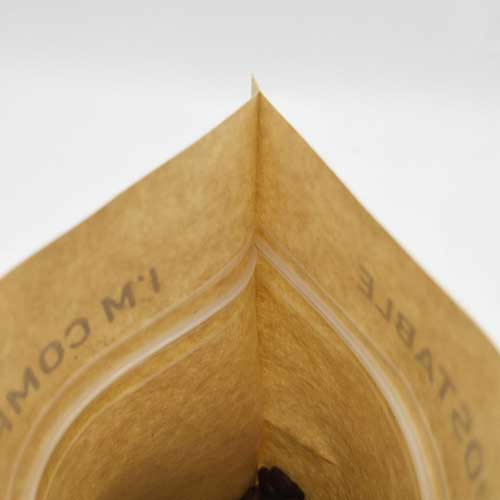

Compostable Pouch With Bottom Gusset

Inside View of Ziplock Compostable Pouch

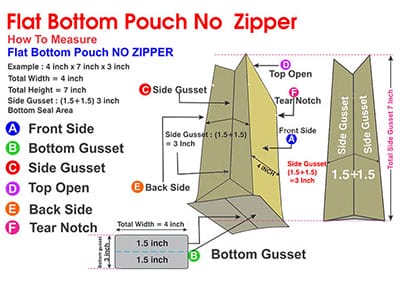

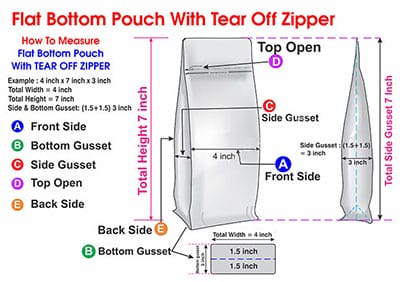

Flat Bottom Compostable Pouch Is Premium Sustainable Packaging

The flat bottom pouch is a new type of compostable packaging that is made from renewable and sustainable materials. It has many advantages over traditional plastic packaging.

It is made from paper or other plant-based materials and it is 100% compostable in industrial composting facilities. The flat bottom pouch can be produced with the same machinery used for paper products, which makes it more economical than traditional plastic packaging, and it can be recycled like paper products as well.

The flat bottom compostable pouch is a premium packaging that is sustainable. It has been designed to be as environmentally friendly as possible and it is made of biodegradable materials. The pouch is made of paperboard and has a flat bottom which can be folded to create an opening.

The benefits of this packaging are that it’s recyclable, bio-degradable, and compostable. It’s also lightweight, giving you the option to choose between different weights for your packaging needs. As a qualified compostable pouch manufacturer, we have been investing costs on the development of production equipment and technology.

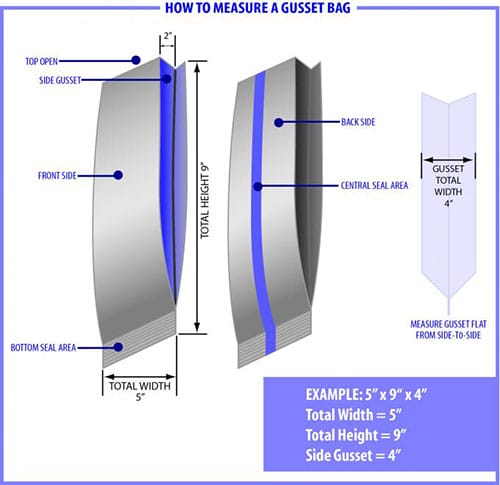

Side Gusset Compostable Pouch Is Best Option For Large Volume

A Side Gusset Compostable Pouch is the best option for large volume. The pouch is made with a side gusset that allows it to expand to accommodate more food and products. The material is compostable, which means that it will decompose in a commercial composting facility or at home.

The pouch can be made of paperboard and lined with a layer of PLA film, which makes it an excellent choice for food storage. It can also be used to pack snack foods.

Side gusset compostable pouch is the best option for large volume because it offers a flexible, cost-effective and environmentally-friendly solution.

The side gusset compostable pouch is the best option for large volume packaging because it offers a flexible, cost-effective and environmentally-friendly solution. The side gusset folds down to accommodate different volumes of liquid or solid content. This allows you to use less material and save on your production costs.

Please contact us, a professional compostable pouch manufacturer, for best suggestions to your brands and products.

Main Accessories For Compostable Pouch: Ziplock & Valve

Compostable Pouches are a new way of packaging food in restaurants. They are made of plant-based materials and can be disposed of easily without causing any harm to the environment. However, ziplock and valve are important accessories for Compostable Pouch.

Ziplock and valve are important accessories for Compostable Pouch because they help keep the content fresh when it is being transported from one place to another.

Ziplocks prevent the content from spilling out while valves help in easy opening and closing of the pouch.

The ziplock and valve are also made of compostable materials.

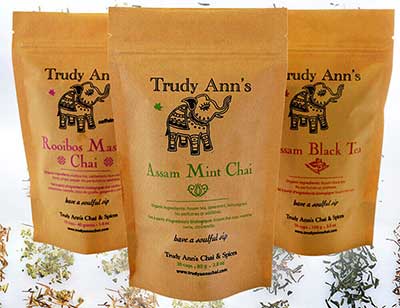

Customization Available: Dimensions & Branded Printing

Compostable pouches are custom-made and branded for the customer. The customized size is made to fit the product, and the branding could be printed on both sides.

The pouches are made from biodegradable materials such as corn starch or sugarcane. They can be used for food packaging, such as cookies, chips, or other snacks. They can also be used for personal care products like shampoo, conditioner and soap.

Compostable pouches are made from a specially formulated, high-quality biodegradable film. This film is manufactured to be strong enough for food packaging, but also delicate enough to break down in a composting environment.

The Compostable Pouch can be customized by dimensions and branded printing. The dimensions of the pouch are customizable and the printing can be done with any design or logo that you want.

Reduce Your Environmental Impact By Using Compostable Packaging!

Compostable packaging is made from plant-based materials, like corn and sugar cane. It can be used for any food product and is 100% biodegradable.

Compostable packaging is better for the environment, better for your health, and better for your wallet. You can save money on plastic wrap and paper bags while reducing your carbon footprint and helping the planet!

Start using compostable packaging today!

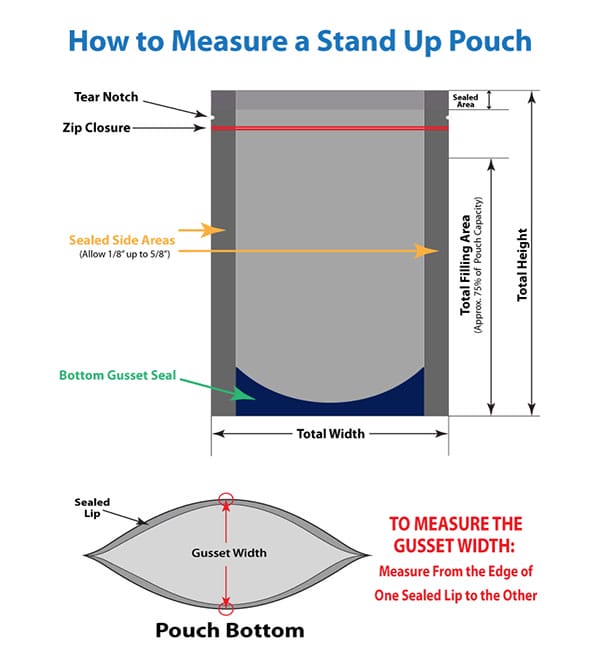

Stand Up Compostable Pouch Size Charts for Reference

All compostable pouches are fully custom-made, including the features of sizes, shapes, colors, printing, etc. The follow size chart is only for reference, not standard.

Different products may go with different size, even they are of same weight.

| Volume (gram) | Volume (oz) | Width (mm) | Width (inch) | Length (mm) | Length (inch) | Gusset (mm) | Gusset (inch) |

|---|---|---|---|---|---|---|---|

| 28 | 1 | 80 | 3.15 | 130 | 5.11 | 40 | 1.60 |

| 70 | 2 | 110 | 4.35 | 160 | 6.30 | 60 | 2.35 |

| 100 | 3 | 120 | 4.75 | 200 | 7.90 | 60 | 2.35 |

| 150 | 4 | 130 | 5.10 | 210 | 8.25 | 60 | 2.35 |

| 250 | 8 | 160 | 6.30 | 230 | 9.05 | 70 | 2.75 |

| 500 | 16 | 190 | 7.50 | 265 | 10.20 | 90 | 3.55 |

| 1000 | 32 | 240 | 9.25 | 335 | 13.20 | 100 | 4.00 |

| 3000 | 106 | 300 | 11.8 | 500 | 17.90 | 70 | 2.75 |

| 4000 | 141 | 380 | 14.9 | 550 | 21.60 | 80 | 3.15 |

100% Compostable pouch with bottom gusset

The 100% Compostable pouch is a compostable food wrapping that is made from a mixture of PLA and cornstarch. This means that it’s 100% compostable in the commercial composting facility, which means that it can be recycled without any problems.

The gusset bottom allows for easy removal of the product from the package, which makes it easier to carry and use.

The bottom gusset will also make it easier to remove food from the pouch without having to use your hands.

Kraft compostable pouch for coffee packaging

Kraft Compostable Coffee Filter Pouches are made from 100% compostable materials and are the perfect solution for your eco-friendly lifestyle.

It’s time to ditch the plastic filters and switch to a healthier, more convenient option. These compostable filter pouches are a simple and cost-effective way to reduce your impact on the environment.

Save money, save time, save the planet — it’s as easy as switching to Kraft Compostable Coffee Filter Pouches.

Compostable pouch with fancy window shape

Packaging is an essential part of our lives, and the use of plastic packaging has been a major concern.

By using a compostable pouch with a fancy window shape, we can reduce the amount of waste that goes to landfills. The pouch is made from corn starch and other natural materials, so it can be recycled at commercial composters.

The design of this pouch makes it easier for users to open and close it. This new design also has a unique shape that allows the pouch to stand on its own. It also has a built-in handle so users can easily carry it around.

Compostable pouch with ziplock

The Compostable pouch with ziplock is a product that can be used to package food products in order to make sure they are not wasted.

The Compostable pouch with ziplock is made from a material that can be composted and does not contaminate the soil. It also prevents food from being wasted by sealing the product in an airtight and resealable way.

The ziplock bag is a common food packaging that is used to store food before it is eaten. It is also a popular choice for storing pet food, as well as other items.

PLA compostable pouch with valve

PLA compostable pouch with valve is a new product that is designed to be eco-friendly and sustainable. It has a valve that allows the user to easily control the flow of liquid, which also makes it easier to clean.

PLA stands for Polylactic Acid which is a biodegradable alternative to plastic. PLA is made from renewable resources such as corn starch, tapioca pearls and sugar cane.

PLA compostable pouch with valve can be used for food packaging, such as salads and other fresh food items.

Food compostable pouch bag

The food compostable pouch bag is a green packaging that is made from natural resources and recyclable materials. It is used to pack food products and make them more sustainable.

Food packaging is a major source of environmental pollution. According to the EPA, food packaging ends up in landfills and causes methane emissions. The use of compostable material for food packaging can help reduce the amount of waste that goes into landfills.

Compostable Stand up pouch for food

Compostable Stand up pouch for food is a type of flexible packaging that can be used to package any type of food or drink. It is made out of 100% recyclable material, which makes it an environmentally friendly solution to use.

The stand up pouch has many advantages over rigid containers such as cans and jars because it takes up less space, offers more protection and can be reused in many different ways.

The stand up pouch offers more protection than rigid containers.

Flat compostable pouch with custom printing

A flat pouch is a sustainable packaging material that can be used for food packaging. This type of packaging is becoming more popular because it is made from natural materials and it provides long-term benefits to the environment.

It’s a sustainable packaging material that can be used for food packaging. This type of packaging is becoming more popular because it is made from natural materials and it provides long-term benefits to the environment.

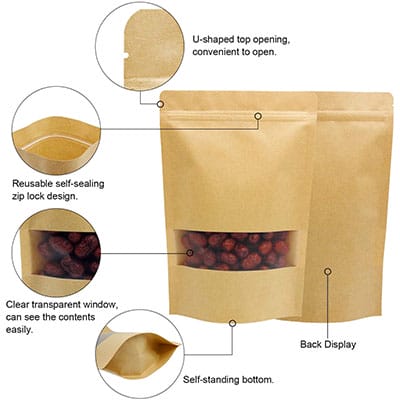

Laminated compostable stand up pouch with window

Food packaging is one of the largest contributors to the environmental impact. Most of the food packaging is made from non-biodegradable materials that are not recyclable.

The Laminated compostable stand up pouch with window has a transparent window in the front that allows consumers to see what’s inside without opening it.

Laminated compostable stand up pouches with windows are environmentally friendly and can also be used as a marketing tool by companies who would like their customers to see what’s inside before buying.

Zip compostable pouch with printing

A zip compostable pouch is a great option for packaging food. It provides the convenience of a stand up pouch and the durability of a ziplock bag, which makes it perfect for use in grocery stores and restaurants.

Zip compostable pouches can be customized with your company logo, brand colors, and information on the contents of the package. They are also great for use in restaurants because they provide an attractive package that will make your food look more appetizing to customers.

Flat bottom Pet food compostable pouch

Flat bottom Pet food Pouch is a stand-up pouch that can be used for pet food packaging. It is made of 100% compostable materials and has a flat bottom, which makes it easy to store in the fridge.

The Flat Bottom Pet Food Compostable Pouch is a stand-up pouch made from natural materials that can be used for pet food, dry cat food, and other dry goods. The pouch is also compostable and recyclable to ensure that it’s environmentally friendly.

Compostable bags with side gusset

Side gusset bags are a type of compostable food packaging that have a side gusset that is designed to make it easy for the user to fill the bag with food.

Side gusset bags are ideal for storing food items and they can be used in a variety of ways. They are often used in restaurants and cafeterias, or by people who prepare their own meals at home.

Side gusset pouch is made from plastic and has a side opening so it can be folded up in different ways.

The Ultimate FAQ Purchasing Guide to Compostable Pouch

Part 0: Compostable Pouch Frequently Asked Questions (FAQ)

Part 1: Definition of Compostable Pouch

Part 2: Applications of Compostable Pouch

Part 3: Compostable pouch Add-on Accessories

Part 4: Compostable Pouch Types

Part 5: Compostable pouch materials guide

Part 6: Compostable pouch manufacturing guide & Quality Assurance

Part 7: Storage and Transportation

Part 1: Definition of Compostable pouch

Compostable pouches, also known as biodegradable bags, are sustainable and eco-friendly packaging that can be composted in a commercial composting facility. They are made of 100% recycled materials and can be disposed of in the trash or recycling bin after use.

Compostable pouches can be used for packaging food, soil, or a plant. They are made from renewable materials like plant-based material and are designed to break down quickly in a compost bin.

Compostable pouches are an eco-friendly alternative to traditional plastic or paper packaging. They can be used to pack food, soil, or plants and they’re recyclable so you don’t have to worry about waste.

Compostable pouches are a revolutionary way to reduce your waste and save the environment. They are made from plant-based materials, which decompose in as little as six weeks, and they break down in a landfill too. Our pouches are also FDA approved, so you can feel safe knowing that your food is being handled with care.

Compostable pouches are a revolutionary new way to reduce waste and save the environment. They are made from plant-based materials and break down quickly in a compost bin, so they can be used again and again. We offer a large variety of colors, sizes, shapes, and styles for your business needs.

Part 2: Applications of Compostable Pouch

It’s time to make a change with compostable pouch packaging.

Compostable pouches are a sustainable solution for your food packaging needs. They’re made from renewable resources, so they’re better for the environment.

Compostable pouches are perfect for a wide variety of products, from dry goods like spices and grains to liquid items like sauces and soups. They’re also available in different sizes, so you can find the best fit for your product.

Find out more about compostable pouch packaging options at our website, or contact us today to learn more!

Main Markets for Compostable Pouches

Roasted Coffee Beans & Ground Coffee

BPA-free, food-grade, and compostable, these pouches are the perfect packaging for your roasted coffee beans

Coffee beans are a sensitive product, and the packaging needs to be carefully selected. These pouches are made from renewable materials that break down in a commercial composting facility. The material is also BPA-free, food-grade, and recyclable.

These pouches are eco-friendly and perfect for your business because it is cost effective, sustainable, and customizable. Order your pouch today!

Pasta and Dried Goods Packaging

We all want to be green. But we also want to enjoy our food. With our compostable pouch, you can have both!

Pasta and dried goods are delicious, but they’re not always the most convenient meal. That’s why we created the best packaging for these foods — it’s airtight and leak-proof, so your food will stay fresh. Plus, it’s compostable and biodegradable, so you can feel good about what you’re doing for the environment.

We’re committed to making sure your food tastes as good as it should and that your meal leaves a minimal carbon footprint on the planet. All of our packaging is made from renewable resources like sugarcane, which is grown without pesticides or fertilizers.

Pet Food & Pet Cares

Today, pet food is a booming industry. Pet food is one of the fastest-growing sectors in the U.S., and it’s estimated that Americans spend more than $20 billion per year on their pets.

Pet food packaging plays an important role in keeping pet food fresh and safe for consumption by pets.

The most popular type of packaging for pet food is a plastic pouch, which can be recycled but not composted.

A compostable pouch has all the benefits of a plastic pouch but it can also be thrown into your backyard compost pile or even your kitchen compost bin to decompose.

Powdered Products Packaging

Compostable pouches are made from renewable, sustainable and biodegradable materials. They are also recyclable and compostable, which makes them a very eco-friendly way to package powdered products.

Compostable pouches offer many benefits over other types of packaging. They are better for the environment, they are more cost effective and they allow you to get your product on shelves faster than before.

Nuts and Seeds Packaging

Compostable pouches are the best packaging for Nuts and Seeds. It is more environmentally friendly than other packaging options because it can be composted in a commercial composting facility.

Compostable pouches are the best packaging for nuts and seeds because they are more environmentally friendly than other options, such as plastic bags or tins. They can be recycled or composted in a commercial composting facility.

The best way to package nuts and seeds is by using a compostable pouch because it is more environmentally friendly than other options, such as plastic bags or tins. Compostable pouches can be recycled or composted in a commercial composting facility.

Candy, Chips, Cracker Packaging

Compostable pouches are the best packaging for candy, chips, and cracker packaging. Compostable pouches are made of biodegradable materials and can be disposed of in a composting facility. These pouches are also lightweight and have a long shelf life, which makes them perfect to store food products.

There are many benefits to using compostable pouches as packaging for food items. They provide protection from moisture and oxygen, which helps preserve the quality of the product inside. Compostable pouches also have a long shelf life because they don’t use any chemicals or preservatives during production.

Pharmaceutical Packaging and Baby Food Packaging

Packaging can be a key factor when it comes to the success of any product. Pharmaceuticals and baby food are not an exception. With the rise in the demand for sustainable packaging, there has been a new innovation in the industry- compostable pouches. They are now being used as packaging for pharmaceuticals and baby food because they have many benefits that make them more sustainable than other options available on the market today.

Compostable pouches are made from plant-based materials like cornstarch and sugarcane, which makes them environmentally friendly and compostable! One of their main benefits is that they can be recycled with other compostables like paper, cardboard, and food waste! Compostable pouches also offer significant cost savings over traditional plastic packaging or glass bottles because

Part 3: Compostable Pouch Add-on Accessories

Different industries go with different packaging, with different features and functions. It’s important and necessary to offer custom-designed stand up pouches to different clients.

Various accessories will be applied to compostable pouches, which will bring many extra functions. It will make it easier for customers and retailers when opening, packing, resealing.

It’s totally customized to use what kinds of add-ons for your bespoke compostable pouch. Or just reach us with the full detail request, we will offer you the best solutions, based on your market demands.

3.1: One-Way Venting Valves for Compostable Pouch

The one-way degassing valve, originally invented and developed by Goglio, has become very important to the development of flexible packaging.

It is produced using raw materials approved by European authorities, the FDA and the Japanese Ministry of Health. But it’s now utilized widely by other markets. One-way degassing valve allows carbon dioxide to escape from a package without allowing oxygen or moisture in.

3.2: Resealable Ziplocks

Resealable compostable pouches are flexible packaging with a pressure seal closure. These compostable pouches are now widely used everywhere.

Such as processing and storing food, retailing items of any size or serving the healthcare needs of patients in hospitals, medical and dental offices, pharmacies, home health care or pharmaceutical production. You almost find these bags.

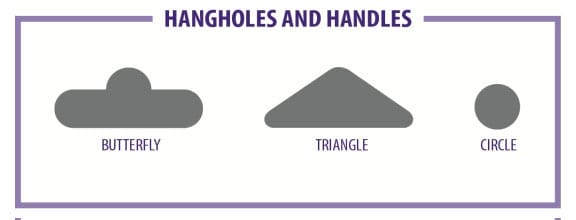

3.3: Hanging Punch Holes

Hanging on the shelf is another way of displaying your products on the supermarket, besides standing up on the shelf.

To meet different demands, we offer 3 different hanging holes: Butterfly (also called Euro) hole / Triangle hole / Round hole. These holes will be done by punching tooling. The sizes of holes are customized as you need.

3.4: Die-cut Handle Grip

Die-cut handles are normally used for pouches with big volume packaging, like spout pouches, dog food bags, pet food bags, merchandise bags.

A plastic handle grip will be use for such handles. It will make it easier and convenient for the consumers when they have to take lots of items after shopping.

3.5: Compostable Pouch Rounded Corners

The bigger pouches, the thicker materials. The thick materials make the pouch strong and stiff enough, but it goes with sharp corners as well.

To avoid any unexpected injuries, we offer the options of rounded corner coffee bags. This will make it safe for all consumers, no matter adults, aged or children.

3.6: Tear Notches

The start for the consumer to use or consume your product is Opening the pouches, easily, without any tools. This is one of the most important factors for a succeed brand.

So we will add tear notches to most of flexible packaging bags, to increase customer convenience.

3.7: Look-Through Windows

Before opening the compostable pouches, how could you touch or smell the content inside? The experienced consumer can tell the quality of coffee bean or ground coffee by seeing.

So a look-though clear window is very important. It’s not difficult to keep some part of the pouch transparent. You can even customize the shape of the window, round, oval or unique shapes.

With look-through windows, it will help to improve the sale of coffee.

Round Shape

Stripe Shape

Unique Shape

3.8: Tin Tie Closures

Compostable pouch with ziplocks enable re-opening and reclosing. What if for a flexible pouch without the ziplock? Tin tie closure will take over the function.

It’s available for some different pouches, not only bottom gusset stand up pouches, also for side gusset bags, flat bottom pouches, kraft paper SOS bags, etc.

With a tin tie closure, it will help to avoid the contamination. And it makes it easier to store the product when it is not finish at one usage.

Part 4: Compostable Pouch Types

It is a new trend in the packaging industry to use compostable pouches for food packaging. It is considered to be the future of eco-friendly packaging.

Compostable pouches are made from plant-based materials and are 100% biodegradable. They can be recycled and decomposed by microorganisms in soil.

The benefits of compostable pouches include:

-They can be made in any shape or size.

-They are sustainable and biodegradable, so they will not harm the environment for years to come.

-They can be made with a variety of materials such as corn starch, sugarcane, potatoes, wheat starch or even bamboo fiber

-The material is very strong so it can hold all sorts of food products without breaking or tearing.

4.1: Bottom Gusset Type

A stand up compostable pouch with bottom gusset is a type of food packaging that is made from renewable resources, such as cornstarch or sugarcane.

Stand up compostable pouches with bottom gussets have been gaining popularity because they offer an environmentally friendly alternative to traditional plastic packaging.

The stand up compostable pouch with bottom gusset has many advantages over other types of packaging. For example, they are more environmentally friendly than other types of packaging because they are made from renewable resources like paperboard or plastics that can be recycled. They are also more economical than other types of packaging because they require less materials to make them, which means that companies have to use less raw materials to produce them.

4.2: Kraft Paper Compostable Pouch

Kraft paper compostable pouches are an innovative and sustainable packaging solution. They are made of a natural, biodegradable material and can be composted in a commercial composting facility.

Kraft paper is a natural product that is made from cotton fibers, wood pulp, and chemical additives. The mixture is heated and pressed to form sheets of paper that can be used for packaging or other purposes. Kraft paper has been around for over 100 years but it was not until the 1990s that it became more popular as an eco-friendly alternative to plastic or aluminum products.

The process of making kraft paper begins with the harvesting of raw materials such as cotton, wood pulp, and chemicals. These raw materials are mixed together in large vats before being heated up to high temperatures.

4.3: Side Gusset Compostable Pouch

Side gusset pouches are a great solution for packaging food items. They are perfect for large volume food packaging because they have a higher capacity than other pouch types. This is because they can be sealed on the side and not just at the top.

A compostable pouch with side gusset is an innovative solution that eliminates the need for plastic bags and provides a more sustainable alternative to standard packaging.

Custom printing is the process of adding your company logo or any other design to a product. This type of printing is usually done on large volume food packaging such as compostable pouches with side gusset. It can be done for both small and large businesses and it is an excellent way to market your company.

4.4: Flat Bottom Compostable Pouch

The flat bottom pouch is a type of packaging that is made out of biodegradable materials. This packaging is also called compostable box pouch. It could be disposed of in a home composting system.

This packaging can be used for any food that needs to be preserved and packaged, such as cereals, cookies, crackers, chips and more. It can also be used for other products like beauty products or soaps. The flat bottom pouch is an environmentally friendly alternative to the plastic bag or the paper bag because it’s made from natural materials instead of petroleum-based plastics.

Compostable pouches are an increasingly popular way to package food. They are made from plant-based materials and can be recycled in a home composting system.

4.5: Square Bottom Pouch with E-zip

There are 2 types of ziplock closures for flexible packaging pouches: regular ziplock and e-zip. regular ziplock.

It will be much easier to open a pouch with e-zip, just catching the tab and pull to the other side. E-zip closure is also called front ziplock, or pocket ziplock. Though it’s a little more expensive than regular ziplock, it’s more popular for coffee stand up pouches.

4.6: Compostable Box Pouch With Tin Tie Closing

There are 4 types of closures for flat bottom Pouches: regular ziplock, pocket ziplock, tin tie closing, and heat sealing. You could choose one of the options according to your promotion purposes.

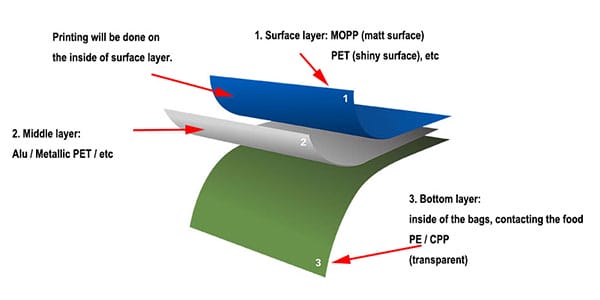

Part 5: Compostable Pouch Material Guide

To keep the content flavor and freshness, a Compostable pouch with the capability to be the significant need. Precisely, when these packages reach to the market consumer, food flavor must be fragrant and taste the same as it is originally.

A compostable pouch from Ouma is a great promotional packaging that could be used as it will encourage purchases. A compostable pouch can be printed with custom-designed artwork, up to eight colours.

Ouma Compostable Pouch are made with the mixture of mainly three distinct layers:

LDPE(Low-density polyethylene): is widely used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic parts for computer components, and various molded laboratory equipment. Its most common use is in plastic bags.

HDPE (High-density polyethylene): is known for its high strength-to-density ratio. This plastic is usually milky white or semi-translucent, has superior puncture, low permeability and temperature resistance, and is more rigid and stronger than LDPE / LLDPE but also tears easier and has a propensity to crinkle.

PVDC: Polyvinylidine chloride, the excellent oxygen and moisture barrier properties of PVDC make it a ideal material for packaging converters. But the high cost of PVDC tends to mean that it is mainly used in the form of copolymers.

BOPP (Biaxially-oriented polypropylene): BOPP films are easy to produce with low costs. They have good chemical compatibility and offer superior moisture vapor barrier properties.

(Kraft) paper: has high tensile strength and elasticity, good tear resistance and is designed for packaging products with high demand for strength and durability. It is used for products like single multiwall paper bags and sacks (for cement, food, chemicals, consumer goods, flour bags etc.), sale bags for bakery products, wrapping.

EVOH (Ethylene Vinyl Alcohol): is produced by a controlled hydrolysis of ethylene vinyl acetate copolymer. It’s most important characteristic is the outstanding Oxygen and odor barrier properties. Packaging structures with EVOH provide high retention of flavors, and prevent quality loss associated with reaction of oxygen with the product.

CPP (Cast Polypropylene): offer excellent heat seal strength, good thermal stability, good puncture resistance, good clarity and fair barrier properties. The film type also has good yield economics owing to its low density. Some of the typical application areas for the film includes hot filling and retort applications, high speed application on FFS machines and bakery products.

PLA (Polylactic acid): Polylactic acid is thermoplastic aliphatic polyester synthesized from renewable biomass, typically from fermented plant starch such as from corn , cassava , sugarcane or sugar beet pulp. In 2010, PLA had the second highest consumption volume of any bioplastic of the world. PLA is compostable, but non-biodegradable according to American and European standards because it does not biodegrade outside of artificial composting conditions.

PBS (Polybutylene succinate) : Polybutylene succinate is a thermoplastic polymer resin that has properties comparable to propylene. It is used in packaging films for food and cosmetics. In the agricultural field, PBS is used as a biodegradable mulching film PBS can be degraded by Amycolatopsis sp. HT-6 and Penicillium sp. strain 14-3. In addition, Microbispora rosea, Excellospora japonica and E. viridilutea have been shown to consume samples of emulsified PBS.

Our compostable pouches can be manufactured by different multi-ply lamination, according to packaging purposes:

- Bio BOPP / Bio CPP

- Kraft // PLA

- PLA // NKME // PLA

- NK // PBS

- Others by requests

The main materials we use for Ouma compostable pouches are certificated by FDA. You could get all our materials certificates by just simply sending us an email.

Part 6: Compostable Pouch Manufacturing Guide & Quality Assurance

A qualified compostable pouch will bring you both a long shelf life span and powerful marketing. It also creates a wonderful emotional connection between your brand and the consumers.

Ouma flex pack has been devoting itself to helping achieve your success in your market. So we take the compostable pouch quality as important as our lives. We focus on each process during production as follows:

1. Order confirmation:

After having your purchase order, we will contact you and confirm each detail via email and telephone. You are welcome to reach us 7*24 by email or phone call whenever you like.

You will have our sales confirmation within 24 hours, including the size, color, add-ons and lastly the purpose. We will specify the requirement or properties you need to be included in your stand up pouch.

2. Down payment:

We will send you the proforma invoice after you sign and send back the sales confirmation. You are supposed to arrange the down payment according to the PI. Normally, it will be 30% to 50% of the order amount.

We will launch the process upon the receipt of the down payment bank slip.

3. Raw materials purchase:

Our production department will prepare all the films, and add-ons like valves, ziplock, spouts, etc.

If there is printing on the pouches, the printing cylinders will be arranged at the same time. It takes 7-10 days for the preparation of all raw materials and stand up pouch accessaries.

4. Printing:

All printing processes reproduce lines and / or dots that form an image. Printing is the process of manufacturing multiple copies of graphic images. Although most people think of printing as putting ink on paper, printing is not limited to any particular materials or inks. The embossing process uses no ink at all, and all shapes and sizes of metals, wood and plastics are common receives of printed messages.

The following major printing processes are used to reproduce graphic images. Each of these processes is suited for specific applications, such as newspaper, book, packaging bags, or textile printing.

–Relief printing:

The relief printing process includes letterpress printing, flexographic printing, and all other methods of transferring an image from a raised surface.

–Intaglio printing:

Intaglio printing is the reverse of relief printing. An intaglio image is transferred from sunken surface. It’s also known as gravure printing, photogravure printing.

–Screen printing:

Screen printing transfers an image by allowing ink to pass through openings in a stencil that has been applied to a screen mesh.

–Lithography printing:

It’s a relatively new process, dating from around 1798. Offset lithographic printing is the most widely used printing process in the commercial printing industry.

5. Composition:

The advent of composites was a revolutionary shift in packaging.Each single material has its own advantages, disadvantages and characteristics.

For example, metallic materials are brittle and not resistant to corrosion, but have excellent barrier properties; LDPE is chemically resistant, easy to heat seal, and easy to process, but its strength and oxygen barrier properties are poor.

Composite can make up for the shortcomings so that a variety of single-performance materials are combined into a new material with comprehensive performance.

The soul of composite flexible packaging lies in the composite, is the superposition of performance. This is also the technical core of the production of composite flexible packaging.

6. Curing:

After the coffee bag roll films are composited, it could not go for slicing right away. Because it takes 72 hours of curing before it’s available for next process. It’s important to make sure it’s a fully curing, otherwise the composite layers may peel off.

7. Slicing:

The roll-form raw material will be cut by slicing machines to exactly the width needed for a pouch. There will be always big quantity of film rolls, the slicing machine will cut with an accuracy of 0.1mm, and keep the roll in perfect conditions.

A perfect slicing will help to speed up the converting process. Otherwise, it will slow the production speed, and waste the raw materials, bringing lots of lots and time and costs.

8. Converting:

Most of the converting job is done by machines. After loading the stand up pouch film roll onto the converting machine, it will go through the first part of the machine, folding according to the pouch type, sealing the bottom and both edges, punching holes, adding ziplock, etc.

9. QC (Quality Control):

Product quality is the basis for the long-term development of enterprises. In order to ensure that all goods meet quality standards, we have established a perfect quality control system:

A. IQC: In-Line QC, there will be 3 production engineers keep checking each section on the production line during the whole production. In fact, the machines have auto monitoring functions, but we still arrange QC checking for 100% assurance.

B. FQC: Final QC: at the end of the production line, there is 1 QC checking each bag, and pick out the disqualified one.

C. OQC: Outgoing QC: before packing to export cartons, we arrange outgoing QC to do another 100% quality checking and pick out disqualified items in the case.

10. Packaging:

After the packaging pouches & bags are through the full QC process, they will be packed by bundles, putting into transparent poly bags. Pouches in bundles will be packed into corrugated cardboard cartons.

The packing quantity of each carton could be indicated by clients, according to different sales methods and purposes. In this way, the pouches will be packed by customized cartons specially for this order, instead of standard size. There will be extra cost for custom cartons.

There could be custom printing on cartons and labels as well. This will also cost a small amount from the client, but it will bring great help to the promotion and storage.

Part 7: Compostable Pouch Storage and Transportation

While the compostable pouch production is finished, we will deliver the cargo and ship them to the client. Before delivery, the compostable pouch will be stored in our warehouse for a couple of days.

The warehouses are in our plants, so all the cargo will be safe and sound before delivery. In most cases, it takes only 15-35 days to ship your cargo from China to you.

We work with professional forwarders for logistics and shipments. They will take care of everything about shipment and send the cargos all over the world. We sell and deliver our goods to more than 40 countries in Asia, Europe, North America, South Africa, and Oceania.

We won’t bother the clients about the shipping and transportation by offering considerate service, including the customs clearance and transit on destination ports. The clients will save a lot of time and trouble from the jobs, just waiting for the cargos at their location.

| Loading Ports | Destination | Port of Discharge |

|---|---|---|

| Shenzhen / Guangzhou / HK | USA | Los Angeles / Oakland / New York / Chicago |

| Shenzhen / Guangzhou / HK | Australia | Melbourne / Sydney |

| Shenzhen / Guangzhou / HK | Netherlands | AMSTERDAM / Rotterdam |

| Shenzhen / Guangzhou / HK | Canada | Vancouver / Toronto |

| Shenzhen / Guangzhou / HK | South Africa | Cape Town / Durban |

| Shenzhen / Guangzhou / HK | Europe | Antwerp / BREMEN / HAMBURG / FELIXSTOWE / Barcelona |

OUMA Compostable Pouch

Ouma is the world’s leading company in the production of compostable pouches and packaging.

The company has been developing and producing environmentally friendly packaging for more than 20 years. Ouma is a professional supplier of compostable pouches for the food industry, healthcare, pharmaceuticals, cosmetics, and other industries.

With us, your business is safe! Your money is safe!

We offer a lowest MOQ request compared with other China vendors. It helps to lower the risks and costs when the client wants to start a new project and make a trial shoot.

We are always there when you need any helps from us, 7*24. You can reach us easily, with email, cell phone, telephone call, whatsApp, Wechat, etc.