What Is The Bag In Box System (BIB)?

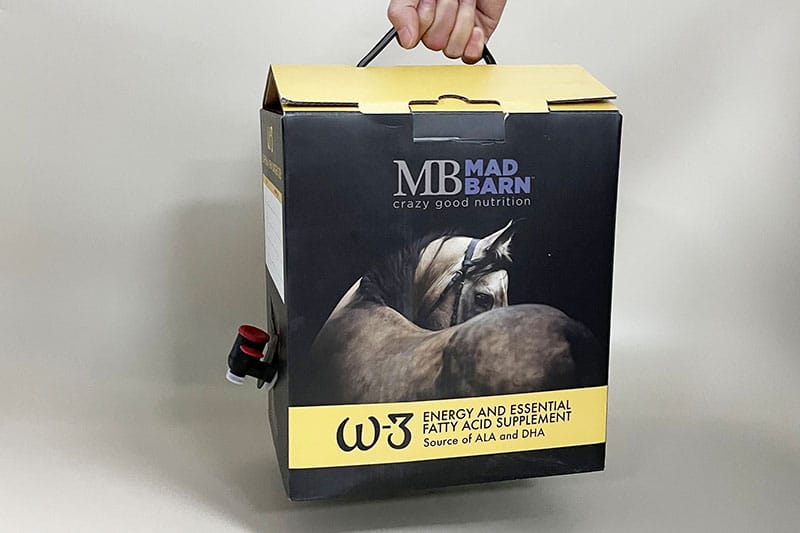

Bag-in-Box packaging consists of a flexible, multi-layered bag placed inside a sturdy, protective outer box. The bag is equipped with a dispensing tap or spout, allowing for easy and controlled dispensing of the contents.

This packaging method is suitable for a wide range of liquid products, from wine and fruit juices to sauces, oils, and industrial chemicals.

The multi-layered bag provides an excellent barrier against oxygen, light, and moisture, preserving the quality and freshness of the contents for an extended period.

The built-in dispensing tap allows for easy, mess-free dispensing of the product, making it ideal for both consumer and industrial applications.

BIB packaging minimizes product waste by allowing complete evacuation of the contents, ensuring that no valuable product is left behind.

Product Features Of Bag In Box System

Bag-in-box systems offer a compelling combination of user convenience, product protection, and environmental benefits, making them an increasingly popular packaging solution across various industries. Here are some key features, expanding on their benefits:

Easy Dispensing

The tap/valve system allows for controlled pouring without the need for lifting, making it convenient for all users, especially those with limited mobility.

The tap/valve mechanism gives the user the ability to dispense the desired amount of product with precision. This is unlike pouring from a bottle or jug, which can be heavy, unwieldy, and prone to spills.

Save Shipping Cost

One often overlooked advantage of bag-in-box systems is their efficient use of space. Both the outer carton and the inner bag can be completely flattened before filling.

This simple feature translates into significant cost savings on transportation and storage.

Imagine trucks capable of carrying twice the number of empty bag-in-box units compared to rigid containers! This space efficiency minimizes transportation costs, which is beneficial for both businesses and consumers.

Custom Designs & Shapes

Bag-in-box systems offer fully customization, allowing you to create packaging solutions tailored precisely to their product and brand identity. This goes beyond simply choosing a size.

The outer box can also be tailored in terms of strength and printing, allowing for eye-catching designs and branding elements that pop on the shelf.

Even the shape of the box can be customized. While rectangular boxes are the norm, variations are possible, allowing for unique shapes.

Various Valves Solution

Bag-in-box packaging offers a remarkable range of valve options, with over 20 distinct types available to suit a wide array of product and dispensing needs.

This variety ensures that clients can select the ideal valve to match the specific characteristics of their product and packaging requirements.

Custom Volume from 1L to Max 220L

Bag-in-box systems offer an impressive range of size options to accommodate various product volumes and applications.

The bags can be customized in capacities ranging from as small as 1 liter up to an expansive 220 liters.

The ability to customize bag-in-box volumes enables businesses to optimize their packaging based on factors like product shelf life, target market, and distribution channels.

Bag In Box By Rotogravure Printing

Custom designs on bag-in-box packaging can indeed be achieved through rotogravure printing. Rotogravure is a high-speed, high-volume printing process that produces high-quality, consistent results, making it an excellent choice for creating attractive and eye-catching designs on bag-in-box containers.

The rotogravure printing process involves engraving the desired design onto a cylindrical surface, which is then used to transfer the ink onto the substrate, in this case, the bag-in-box material.

Why Choose Ouma As Your Packaging Partner

Real Manufacturer

Ouma is a leading flexible packaging manufacturer that has been serving the industry since 2000, with 100% self-owned plants.

With years of experience and expertise, Ouma is committed to providing high-quality and innovative packaging solutions to meet the unique needs of our customers.

Ouma offers a wide range of flexible packaging products, including Mylar bags, stand-up pouches, flat bottom pouches, retort pouches, flat pouches, and more.

These products are available in a variety of sizes, shapes, and colors, and can be customized to fit the specific needs of each customer.

At Ouma, quality and customer satisfaction are top priorities. Ouma uses only the highest quality materials and employs strict quality control measures to ensure that our products meet the highest standards of excellence.

Frequently Asked Questions (FAQ)

Related Stand Up Pouches For Your Reference

If you’re interested in stand up pouches, be sure to check out the wide range of products offered by Ouma. In addition to stand-up pouches, Ouma also produces a variety of packaging solutions to meet your needs. Ouma offers flat pouches, gusseted bags, side-seal pouches, and more. To browse other products, click the following links and explore other product categories.